Esper's Innovative Photogrammetry Solutions Powered by Sony

Nottingham, UK-based Esper specialises in designing and manufacturing photogrammetry rigs. This technology uses digital imagery of physical objects to recreate them in 3D space. The company supplies Sony cameras to its customers exclusively because of their extremely detailed images, value for money (essential when each rig requires so many cameras), and the Sony Camera Remote SDK, which provides customised remote control of virtually all the cameras’ functions.

Esper’s work is at the intersection between flat, still photography and the fast-growing spectrum of digital 3D objects and worlds. Its customers include game & VFX studios, academia, advertising and cultural heritage organisations. 3D capture is the crunch point, where the real things become digital representations, and accuracy is everything.

Increasingly sophisticated game platforms require photogrammetric content for their software products. Generative AI models also require digitised 3D image data for training.

Esper is not a conventional studio. Instead, the company designs and builds capture rigs that make 3D and volumetric capture simpler, more consistent and efficient for its clients.

3D capture

Photogrammetry is where real, physical objects are captured digitally from multiple directions, producing outputs that are viewable from all angles. Capturing objects in this way creates 3D representations that can then be used in a range of applications.

These multi-directional images are processed to create realistic 3D models for use in games, virtual simulations and many other applications that require robust images that viewers can see from any direction.

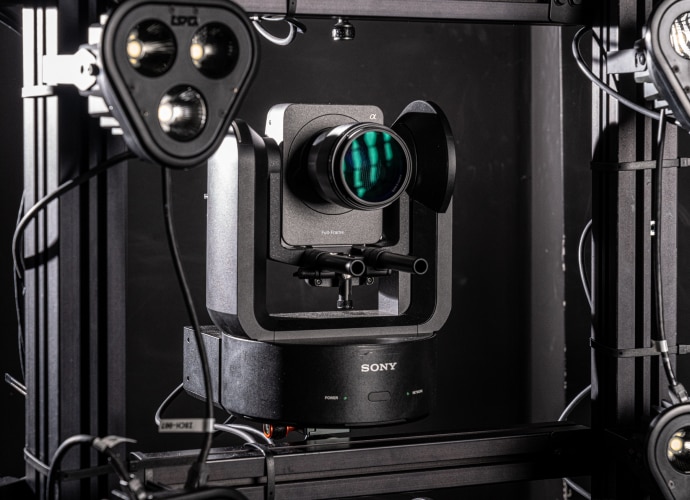

Esper’s capture systems use conventional photography but in very specific ways. There is a rig that forms a skeletal sphere around the object to be captured. The rig has a large number of identical cameras at regularly spaced points to ensure coverage from every angle.

Crucially, the rig also includes proprietary lighting and a control mechanism to trigger the cameras and lights. With so many cameras involved, it’s essential to have precise control of the camera shutters and be able to configure the camera settings. Esper’s photogrammetry rigs solve multiple requirements for 3D capture.

The resolution available in the Sony large sensor cameras now is absolutely superb for textures. They give you a level of detail that’s just not possible with other sensors.

Nick Foots

Esper company

Image quality, control and synchronisation

The ultimate quality of the final 3D scans depends on the capabilities of the cameras used in capturing the images and textures. That’s why Esper supplies Sony cameras exclusively. The cameras need finely-grained control, either to fire them all simultaneously or in a predetermined sequence, as in, for example, photometric captures.

We want to automate the process as much as possible. We use closed feedback loops between the platform’s lighting, software and processing to optimise the process.

Nick Foots

Esper company

Turning around a skills shortage

Esper’s products are in demand because the rapidly growing field of photogrammetry has led to a skill shortage: there simply aren’t enough professionals with the experience to configure and operate an industrial-scale photogrammetry facility. Supplying a fully operational rig with cameras, lights, and control mechanisms makes it easier for the much larger talent pool drawn from conventional photography and the game industry to use photogrammetric techniques in their workplaces.

3D, 4D / Volumetric capture and beyond

Esper is on the cutting edge of image capture for 3D and 4D / volumetric applications. Multiple industries, from universities to game developers to marketing companies, are looking into the advantages of spatial photography.

Photometric Stereo

The accuracy of photogrammetry can be increased by using photometric stereo, where, if you capture in the highest possible resolution, you can effectively reproduce the surface direction of every pixel.

Esper’s rigs are ideal for acquiring photometric stereo images. Under software control, the cameras take multiple pictures of an object, each lit from a different angle. From the different amounts of light reflected from the surface, it is possible to calculate the Surface Normal, a notional line perpendicular to each surface.

The technique gives enough detail to represent the overall direction and orientation of an objects surface and its texture. Specialist 3D software that combines the multiple cameras’ outputs into a realistic 3D model can be used by subsequent applications to accurately illuminate the objects in their final role in a computer game or industrial simulation.

We switched to Sony cameras for a couple of factors. One was that there was a wider selection of mirrorless cameras available; they’re more suitable for us because of the low shutter lag and higher frame rate, and the other is big, high-resolution sensors.

Nick Foots

Esper company

The future

Consumers and professionals are gaining access to an increasing array of 3D-capable displays like Sony’s immersive spatial content creation system https://www.sony.net/corporate/information/news/202401/24-001E/ for creators and Apple’s Vision Pro for consumers.

Esper’s approach to meeting the demand in the future is to make the process as automatic as possible with its 3d and volumetric rigs that combine lighting, cameras and control in a single package. Photographic quality is crucial in photogrammetry, as is the ability to control multiple cameras precisely through bespoke software. Esper has chosen Sony as its primary camera supplier not only because of Sony’s decades of experience in digital imaging but also because of the ongoing development and support from the Japanese camera company.

The SDK is the biggest thing because it gives us almost complete control over every setting on the camera. When we’re trying to systematise the cameras - with up to 120 of them in a single rig - it really helps.

Nick Foots

Esper company