Optimised medical printers and print media: Sony develops both to ensure the highest quality

From the 1980s to the present day, Sony’s reliable printer technology has provided stable, high-quality prints to medical facilities. Two Sony engineers tell us about this technology and their work in developing it.

Right: Y. Hirumi, engineer in charge of printer development

Left: S. Narumi, engineer in charge of print media development

What are the features of Sony’s medical printers?

Hirumi: Sony’s medical printers use a direct thermal method. In this method, a thermal head makes direct contact with thermal paper and uses heat to record an image. The precise heat transfer reproduces smooth gradation within images and a high print quality. Plus, because it doesn’t require ink or ribbons, the printer can be virtually maintenance-free and compact, making it easy to mount on medical carts.

Of course, both the printer and the print media must be perfectly matched. Sony developed both, allowing us to optimise the design of each.

Thermal print head installed in Sony’s medical printer UP-898 series

How are printers and print media optimised?

Hirumi: The shape and surface properties of the thermal head, and the composition of the recording layer of the thermal paper, are vital. High-quality printing depends on precise heat control for the head, accurate heat transfer, and smoothly running thermal paper.

We also place great importance on reliability during the development process. By carefully composing the thermal recording layer of the media, and optimising it with the surface of the thermal head, we can avoid multiple issues. These include avoiding streaks from dirt adhesion, and preventing disconnection by electrostatic breakdown and corrosion of the head.

Narumi: We’ve designed the surface components of the print media so that the thermal head has a self-cleaning function. If the cleaning were too robust, the head would wear out. If it were too weak, the print media would stick to the thermal head and you might get hard burn-in. Either way, you might get scratches in the prints.

At Sony, the printer engineering team closely collaborates with the print media development team, so we can design and verify the right balance to achieve high quality printing.

Check the surface condition of the thermal head with a microscope

How do you conduct quality inspections?

Narumi: In a large hospital, we could assume 10 patients per day and three prints per person. That makes 210 prints per week, equivalent to about 55,000 prints (250 rolls) in five years. Our goal is to handle this number of prints without any issues, and we’ve actually printed that much over several months to check if there is any deterioration in image quality. Durability is also vital. We design the functional layers of the print media so they can operate at a range of temperatures and humidity levels.

Environmental test for print media, changing temperature and humidity

Narumi: At the factory, a functional layer is applied to the base material of the print media, which is thousands of meters—even tens of kilometers—long. During process inspections, high-speed diagnostic imaging equipment checks for coating defects and any foreign objects on the base material as it flows past at high speed.

The information gathered is then sent to the post-process, where all defects are eliminated before finishing the product. These products are then inspected again before shipment, where we actually print and perform a colour rendering inspection of gray gradation. This close quality control is all designed to ensure the reproducibility of the monitor image doesn’t change.

Carrying out a large number of prints under environmental load

Hirumi: We have a printer that we use as a reference machine to ensure the quality is maintained for many years. Manufactured printers are adjusted to match the reference machine before shipping.

Checking gradation reproducibility

Hirumi: Because it’s a direct thermal system, the mechanical components (including the thermal head) and the print media are in direct contact. So, in the development stage, matching the mechanical and print media is very important. That’s a big difference from inkjet printers, where the recording device and photographic paper don’t come into contact.

Narumi: Four teams work together in development, working on mechanical components, print media, electronics and software. This allows us to verify the safety and quality of printers and media at an early stage, accelerate development, and spend less time and money on solving issues that might arise. It’s also very helpful that the four teams can gather and share information about customer needs, splitting this important workload between them.

What is the superiority of genuine print media?

Narumi: We don’t develop just looking at the immediate print performance. We’re always thinking about durability and guaranteed operation in a variety of environments, and we conduct cargo transportation tests, mimicking storage and transportation conditions. We think and design at a high level, from the materials to the storage stability of printed images.

Some of the inexpensive print media on the market seems to damage the thermal head after printing just a few dozen copies. That’s why Sony’s warranty covers only genuine products. When you consider the printer repair cost, and its downtime, I think the running costs of the genuine print media are worth it.

What direction of evolution will Sony’s printers and print media take?

Hirumi: The UP-898 series is mainly used as a printer for ultrasound diagnostics. Ultrasound diagnostic equipment has become smaller in recent years, and the power supply required for printers has switched from AC to DC power. Right now, we’re looking for more miniaturisation, more weight reduction, and less power consumption for printers, matching the trends we see.

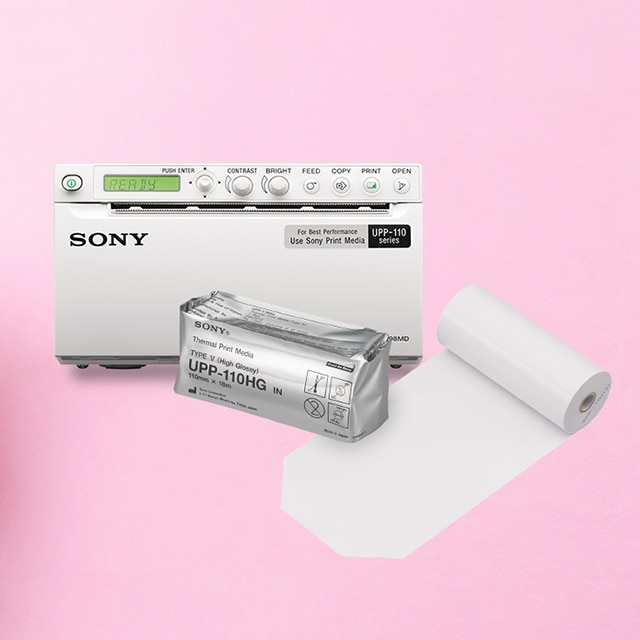

Narumi: Sony’s standard print media, the UPP-110S, has been on the market since 1986—nearly 40 years. Even the newest, premium grade, UPP-110HG, has been on the market for about 25 years. In that time, six generations of printers have launched.

We’ve always needed print media that works with all generations of printers, so it has evolved. We are constantly checking and evolving to meet the compliance and chemical substance regulations of each country.

What are your expectations and dreams as an engineer?

Narumi: As IT systems spread across hospitals in developed countries, some people said that print would not be necessary in future and the “printless” age would arrive. However, even where IT systems are available, I think the value of prints remains, depending on local culture and values—or the insurance system.

Personally, I’ve kept all the ultrasound images from before my child was born in an album. They’re important family memories.

In emerging countries, the introduction of high-grade medical equipment has only just begun, and we believe that it will take time to develop the right IT infrastructure. And that makes printing in their medical facilities essential.

We would like to continue developing and expanding the printer market, supporting our customers and contributing to the wider medical industry.

Hirumi: Digital storage, on servers and clouds, makes it possible to store a huge number of images. But in order to quickly access the specific data that you want, there’s a lot of preparation needed, such as setting up the IT environment, and building and maintaining an accurate database. For better or worse, prints are paper, so they’re easy to handle. And if it’s kept with a patient’s chart, medical staff can access it even in the event of a power outage or system failure.

The number of hospitals with electronic medical record systems is steadily increasing, especially in developed countries. However, many of them still keep prints because there’s an existing culture or a need for keeping records ‘on paper’.

To that end, we believe that what Sony must do as a manufacturer is to enable easy-to-use, inexpensive printing. We will continue to develop medical printers and dedicated print media with the ‘value of printing’ firmly in our minds. There’s still lots for us to do as Sony engineers.

We will continue to develop medical printers and dedicated print media with the ‘value of printing’ firmly in our minds.

Y. Hirumi

Engineer in charge of printer development

History of Sony’s Medical Printer

The history of Sony’s medical printers began in the 1980s. Polaroid photographs were mainstream for printing from ultrasound diagnostic equipment at the time, but there were many restrictions and it was difficult to print in medical facilities. It took more than a minute to fix the image on the paper, the cost per print was high (150 to 160 Japanese Yen) and you could only line up 10 print papers at one time.

In response, Sony turned to the graphic printer for Videotex* they were developing at the time. This used a heat control method via a thermal head that reproduced the gradation of each pixel, as well as dedicated thermal paper that suited that kind of gradation reproduction. The UP-811, released in July 1986, incorporated this technology, supported by feedback from medical device manufacturers and medical professionals.

This era-defining black-and-white printer gradually attracted the attention of major medical device manufacturers, who—one by one—adopted it for their own medical systems.

(*A network system that used a television as a terminal to send and receive text, images, and videos over a telephone line)

Thermal video printer for ultrasound diagnostic equipment “UP-811 (left)” and Medical A5 colour video printer “UP-5000 (right)”

Contribution of Sony’s Medical Printers to the Medical Industry

The UP-811 was a breakthrough in printing for conventional ultrasound diagnostic equipment. It could deliver a photo-quality print, at a cost of about 10 Japanese Yen, in less than 10 seconds. This marked the beginning of the daily use of black-and-white ultrasonic printers in many clinical departments, from obstetrics to gynaecology to internal medicine.

After that, Sony developed the world’s first sublimation transfer colour printer, and in 1988 released the UP-5000. This reduced printing time, weight, and price to one-third that of the previous model, and was soon used as a printer for images from flexible endoscopic equipment.

Since those days, Sony has expanded its line-up for diagnostic imaging equipment, such as ultrasound, radiation, and endoscopes. We continue to provide the medical industry with affordable, high-quality, easy-to-use medical printers—black-and-white and colour—alongside our many other medical technologies and products.